The latest update on D1048 was provided by Mike Targett at the WLA’s Annual General Meeting held on the 15 November 2025. All images and footage courtesy of Jeff Targett, Mike Targett, Mike Tromans & Sally Sheldon….

Electrical

The new set of batteries have had all connections fitted and are now fully prepared to be connected to D1062. With D1062 being called to cover services due to the summer steam ban, as well as an already hectic schedule, there was simply not a sufficient gap in D1062’s operational commitments to remove Courier’s set of batteries. As a result, the new set of batteries have been temporarily fitted to D1048 so they can be put on charge to preserve their longevity. Naturally this opportunity has not been missed to progress Lady’s electrical assessment.

Dyno starters

Both dyno starters have had their inspection covers removed for visual inspection of comm and brush gear. “A” end was found to have 3 of the 8 brushes seized, one of these seized brushes has been freed with the other two being a work-in-progress. “B” end has all 8 brushes free. All 4 supply cables on “B” end dynostarter have been subject to insulation testing and are within specification.

Final drives

All 3 final drives on “A” bogie have received an oil change. As part of the oil change the opportunity was taken to assess the final drives. Once the existing oil was drained the bottom plate housing the oil pumps were removed and internal areas inspected. All 3 oil pumps were found to be in working order in both directions, cleaned and filters removed and themselves cleaned. All visible bearings and surfaces are as expected. Fresh oil inserted following completion of each individual assessment. Additional attention was given to final drive #2 (centre axle) as this is the final drive reported to have run hot many years ago. Final drives 1 & 3 were reported to be in “very good” condition following everything looking as expected after visual assessment.

The entire internal area of final drive #2 was cleaned to assess it’s internal condition. Slight signs of water ingress was evident with mild corrosion and slight pitting visible on internal casing and pump body. Old oil was found to emulsified. Old oil was put through a sieve with no debris of any kind collected. No bluing visible on any surface whatsoever, including gears and bearings. Small bearing also assessed and discovered to be in good condition with no play, another very encouraging sign.

Air Brakes

D1048 has received an initial air brake assessment.

With the air brake system back fed two massive air leaks immediately presented themselves. Their locations and cause are as follows:

- Behind “B” side valance due to a missing spirax valve.

- “B” end cab. The cause found to be all three connections to the main air reservoir control box being disconnected.

D1048’s Spirax valve has since been located.

The WLA have yet to confirm but during the hand over procedure of D1048, the previous owners informed the WLA that a section of air brake pipe, underneath the engine room floor at “B” end, was found to be badly corroded and removed.

Spirax valve to be re-fitted, air reservoir control box connections to be remade and a new section of air brake pipe to be installed, to progress air brake assessment.

Vacuum Brakes

Both vacuum exhausters have had their inspection covers removed, comm and brush gear assessed. Internals of both exhausters looked to be in very good condition. All 8 brushes on exhauster #1 were found to be free. Both vacuum exhausters have been energised from switches on Davenset and both ran as expected with no issues reported.

Both vacuum exhausters operational.

We are unable to verify the integrity of the vacuum brake system as all 4 vacuum gauges (2 in each cab) have been removed.

Vacuum gauges to be replaced to progress vacuum brake assessment.

Miscellaneous

The damaged-beyond-repair due to water ingress internals of “A” end overspeed unit have been replaced with a spare.

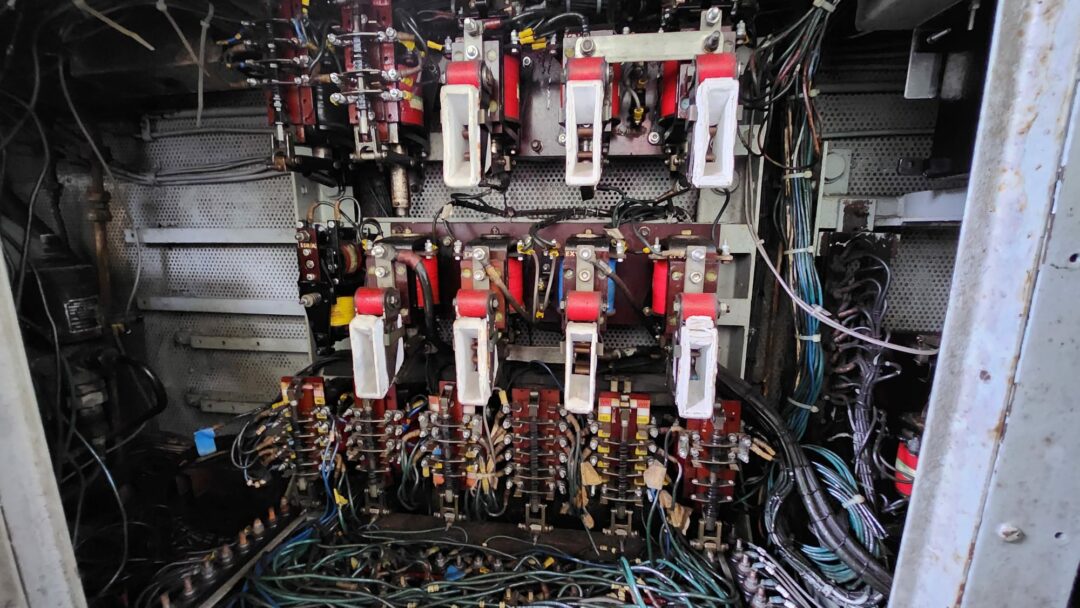

Electrical Control Circuits

The 2 major earth faults at “A” end have been revisited. The 2 cables have been traced through to the instruments they supply and disconnected. Both wires were then earth tested again to find, on both counts the faults remain. This proves that the major earth faults are with the wires themselves and not the equipment they supply. Further investigation required.

Electrical Power Circuits

With “B” end dynostarter having passed megga testing and found to be free, “B” end oil pump was then run to lubricate “B” end engine, showing 80 psi at the engine oil pressure gauge. With the new set of batteries fitted “B” end dynostarter was energised and successfully turned over “B” end transmission, which in turn, turned over “B” end engine and “B” end serck pump. All four components responded as expected with no issues reported.

Based on the above we are now in a position to make the following statement:

“The WLA can confirm, that on the ELECTRICAL POWER side D1048, in her current condition, is capable of starting “B” end engine”

Following this milestone success, the team of working members involved have set about trying to achieve the same results from “A” end.

“A” end engine oil priming pump was previously reported to be unresponsive when energised. “A” end oil pump has been revisited. On secondary inspection it was found that despite the full 110v leaving number 1 electrical frame 0v were arriving at the pump motor. The wires in question were traced to the nearest electrical junction box were the wires were retested. The full 110v were recorded at this point. “A” end oil pump motor was then separated from the pump itself and, using “A” cab desk as a temporary work bench, it was discovered that the motor had a missing brush, missing cable gland and the comm to be very dirty. The comm was cleaned, a replacement brush sourced and fitted, a replacement cable gland sourced and fitted, and, using off-cuts from D1013’s re-wire, the motor re-wired with approximately 1 metre long tails. The motor was then energised on “A” cab floor and ran. The motor was then re-fitted to “A” end oil pump with the new wiring pulled through the existing electrical conduit and connected to the original wiring in the aforementioned electrical junction box. “A” end oil pump was then energised via the oil pump relay under the desk at “A” and ran with no issues reported.

“A” end engine oil priming pump now operational.

“A” end engine dipstick was then dipped and found to be bone dry.

“A” end engine to be filled with engine oil and the last 2 seized brushes of “A” end dynostarter to be freed in order to progress “A” end engine, “A” end oil pump, “A” end transmission, “A” end Serck pump, “A” end dynostarter and “A” electrical power circuit assessments.

Further updates to follow…!

Mike Targett